- About Us

- Products

- Hot Products

- Applications

- Services

- Supports

- Order Center

- Contact Us

Karanwal, Neha, et al. Chemical Engineering Journal 498 (2024): 155603.

Karanwal, Neha, et al. Chemical Engineering Journal 498 (2024): 155603.

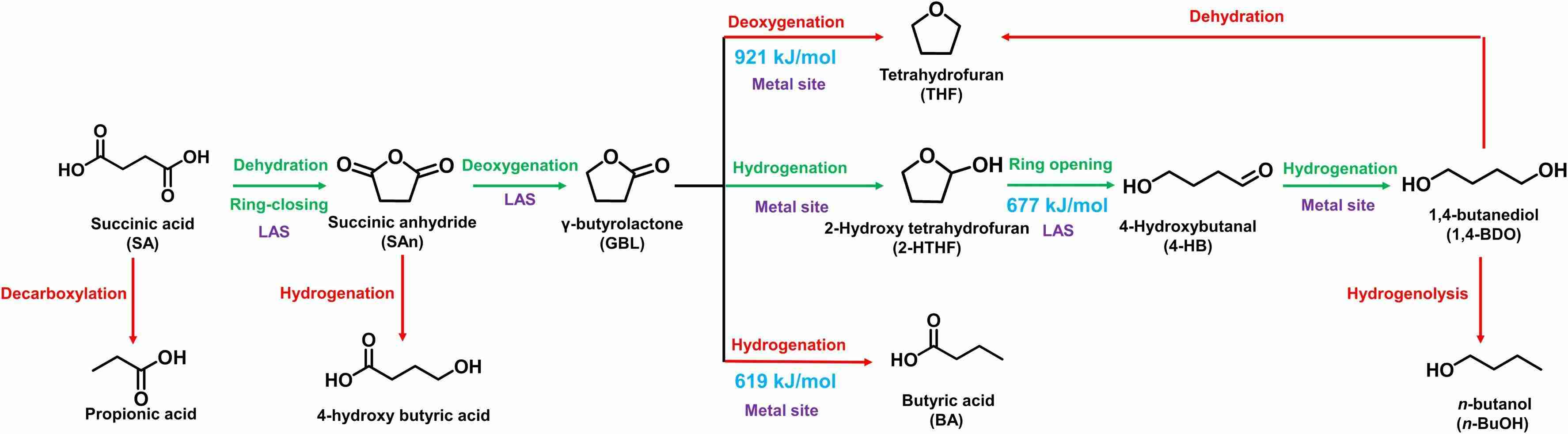

The direct conversion of succinic acid (SA) to 1,4-butanediol (1,4-BDO) was successfully achieved using a rhenium-promoter-free Ru-OvZrOx catalyst, producing 1,4-BDO with a high yield of 89.5%. The catalyst, composed of ruthenium (Ru) nanoparticles deposited on oxygen-vacant zirconia (OvZrOx), effectively facilitated the reaction under mild conditions (200 °C, 5 MPa H₂) with a space-time yield (STY) of 0.19 h-1. The interaction between Ru and OvZrOx stabilized the Ru nanoparticles, promoting hydrogen spillover, increasing catalyst acidity, and enhancing intermediate adsorption.

The reaction mechanism was driven by a hydrogen-shuttling process where Ru0 dissociated hydrogen, which then migrated to Zrδ+ sites, actively participating in the hydrodeoxygenation and hydrogenation steps. This facilitated the conversion of SA into 1,4-BDO through a series of intermediate reactions, including the dehydration of SA to succinic anhydride, followed by ring-opening and reduction steps. Detailed DFT simulations and isotopic studies confirmed this process.

Notably, the Ru-OvZrOx catalyst demonstrated excellent stability, maintaining high efficiency over six consecutive runs. This study positions succinic acid as a key intermediate in the sustainable production of 1,4-butanediol, offering an alternative to conventional rhenium-promoted catalysts.

Liu, Song, Guojun Cheng, and Zhongfeng Tang. Particuology 90 (2024): 209-217.

Liu, Song, Guojun Cheng, and Zhongfeng Tang. Particuology 90 (2024): 209-217.

Succinic acid has been investigated as an effective crystal modifier in the synthesis of anhydrous magnesium carbonate (MgCO₃) particles. Using a hydrothermal method, the addition of succinic acid was found to significantly influence the morphology and particle size of MgCO₃. At pH 9-11, temperatures between 160-200 °C, and reaction times of 3-9 hours, succinic acid (0.003-0.005 mol) was able to induce a gradual transformation of the MgCO₃ particle shape from diamond-like to more uniform and cube-like forms, with an average particle size ranging from 3.3 to 7.5 μm.

The morphological changes were attributed to the interaction between succinic acid and magnesium ions, with the acid modifying crystal growth dynamics. Particularly, the presence of succinic acid helped reduce particle agglomeration, especially at pH 9, where particles tended to cluster more easily. The study also revealed that the most favorable conditions for producing high-quality, uniform MgCO₃ particles with well-defined crystal structures were at a temperature of 180 °C for 6 hours.

This research underscores the role of succinic acid as a powerful additive for controlling particle morphology, offering potential for fine-tuning materials in various industrial applications requiring precise control over particle size and shape.

Xu, Tingting, et al. Chemical Engineering Journal 487 (2024): 150466.

Xu, Tingting, et al. Chemical Engineering Journal 487 (2024): 150466.

Succinic acid (SA) has emerged as a key bioenergetic mediator in the design of novel hydrogels for spinal cord injury (SCI) repair. In this study, a bioenergetic chitosan (CS) hydrogel was synthesized by incorporating SA, a vital intermediate in the tricarboxylic acid (TCA) cycle, to promote cellular energy supply. Upon degradation, the SA released from the hydrogel fueled oxidative phosphorylation (OXPHOS) and enhanced cellular bioenergetic levels, driving neuronal differentiation and facilitating axonal elongation in vitro and in vivo. The hydrogel significantly boosted the expression of neuronal differentiation markers, achieving a 1.5-fold increase in differentiation compared to control groups.

Mechanistically, the increased bioenergetic levels triggered the AMP-activated protein kinase (AMPK)-mammalian target of rapamycin (mTOR) axis, promoting neuronal differentiation. Additionally, ATP released from the hydrogel activated the P2X7 receptor, leading to increased intracellular calcium and MAPK signaling, which further supported neuronal differentiation. In vivo, the bioenergetic CS-SA hydrogel improved spinal cord injury repair and functional recovery.

This work underscores the potential of succinic acid as a powerful bioenergetic unit for modulating cellular metabolism and enhancing nerve regeneration, offering a promising strategy for SCI treatment and bioenergetic-active material design in tissue engineering.